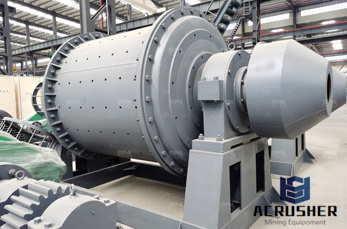

Ball Mills

Ball mills designed for long life and minimum maintenance overflow ball mill sizes range from 5 ft. x 8 ft. with 75 HP to 30'' x ... from an empirical formula.

WhatsApp)

WhatsApp)

Ball mills designed for long life and minimum maintenance overflow ball mill sizes range from 5 ft. x 8 ft. with 75 HP to 30'' x ... from an empirical formula.

useful formulas 2 required formula note design power pd pm x fs pd design horsepower hp pm motor or normal running power hp fs ... ball mill design for mine firing ...

ball mill design calculation xls and file ... The basic parameters used in ball mill design ... will be BW Ball Mill Sizing Example Calculation Formula.

rolling mill speed calculation formula . ball mill speed ... Durham ETheses Rolling mill roll design . The method or formula for the calculation of each parameter is ...

On Jan 31, 1989 Magdalinović published: Calculation of energy required for grinding in a ball mill

Ball Mill. Group No. 3 LOGO Contents Introduction Types and Process Principle of work Description of Ball mill Design and Cost Introduction

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Rod mills are very similar to ball mills, except they use long rods for grinding media. The rods grind the ore by tumbling within the the mill, similar to the ...

ball mill design for 100 kg feed ... ball mill operating parameters for copper chromium ... 4 hi cold roll mill housing load formula; condux mill; Products.

In spite of a great number of studies in the field of fracture schemes there is no formula known which connects the technical grinding work with ... Ball mill A ...

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls ...

Ball Mill Design Calculation . É High Capacity É . PSP Engineering has continuously refi ned the design of its ball mills. . IEEEIPCA Cement .

Mar 08, 2013· calculation of ball mill grinding efficiency. dear experts . please tell me how to calculate the grinding efficiency of a closed ckt open ckt ball mill.

The circulating load ratio is known to be an extremely important design ... a valid "massbalance" formula can be derived from ... A ball mill circuit product ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Mar 10, 2011· How Can I calculate new ball size and weight desing for ... dont know formula for ball size and weight design. ... new ball size and weight desing for ball mill.

How to Size a Ball Mill Design Calculator Formula 911 . The sizing of ball mills and ball milling circuits from laboratory grinding tests is . >>Chat Online;

New Liberty ball mill foundations completed and construction update ... ball mill design calculation in ... The formula of radiation damping is derived ...

How to Size a Ball Mill Design Calculator Formula Mineral . Oct 23, 2016 Estimation based on FLSmith (Krebs) Capacity Correlation.

Understanding Ball Mill Sizing. L. G. Austin. ... Industrial Engineering Chemistry Process Design and Development. Stewart, Weisman, Goodwin, Speight.

Ball Mill Presentation ... Introduction Types and Process Principle of work Description of Ball mill Design and Cost ... Formula Book Cement Industries.

Design and Optimization of Ball Mill for Clinker ... The laboratory ball mill has length 50 cm and diameter 30 cm ... These design equations and calculations are ...

Download Songs Ball Mill Calculation Data In Pdf only for ... GRINDING BALL MILL LOAD CALCULATION FORMULA . Listen. Download. COAL BALL MILL DESIGN CALCULATIONS . Listen.

Description: ball mill calculations. ... (Mill output Rf Formula3 ... ball mill design. Fuel and Combustion calculations.

WhatsApp)

WhatsApp)