Coal Pulverizer Maintenance Improves Boiler Combustion

Optimized coal pulverizer performance is a prerequisite for furnace combustion efficacy. Here are some solutions for overcoming common combustion problems.

WhatsApp)

WhatsApp)

Optimized coal pulverizer performance is a prerequisite for furnace combustion efficacy. Here are some solutions for overcoming common combustion problems.

COAL PULVERIZER DESIGN UPGRADES TO MEET THE . 5 Today''s coalfired utility boiler operation needs pulverizer designs to supply pulverized coal with required ...

Combustion Engineering 783RP BowlMill Coal Pulverizer. enclosed chamber with wear resistant plates. The hammers impact on the coal, crushing it against the plates.

Performance Driven Maintenance of Coal Pulverizers ... By conducting periodic Isokinetic coal sampling pulverizer ... This was a ball tube mill and the issues ...

Presentation. On Maintenance of coal mill and coal feeders Coal Mill Coal pulverizer pulverizer/mill /mill system: One of the critical power plant components that is ...

coal mill pulverizers in power plants – Mining equipment . Ball Mill for Coal Plant,Ball Mill Coal Burning Power Plant for . Ball Mill Coal Burning Power Plant.

Coal crusher, coal mill, coal crushing plant, coal grinding equipment, coal processing plant, coal screening washing plant, coal pulverizer.

Coal pulverizing in power stations. Pulverizing coal consists in grinding coal as fine as possible prior to combustion in the steamgenerating furnaces of fossil fuel ...

Obtain superior wear part performance for EL type coal pulverizers, including: top and bottom grinding rings, housing units, grinding balls, and more.

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for ...

A Comparison of Three Types of Coal ... A COMPARISON OF THREE TYPES OF COAL ... of the Riley Vertical Roller Mill with Riley''s two other pulverizer ...

The SAS Line Blank Isolation Valve is an economical and effective way to isolate a coal pipe. Constructed out of heavyduty A36 steel for a long service free life.

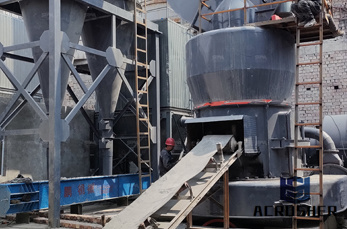

Coal pulverizer is a mechanical device used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel power plants.

MBF Mill Coal Read more about rotating, reduces, stationary, airports, products and upgrades.

The fineness of the coal is also important in overall mill efficiency and in reducing ... Coal Pulverising in Boilers. ... The purpose of a pulverizer in a coal fired ...

Coal mills manufacturer SBM design coal mill pulverizer for steam power plant, supply coal mill maintenance, operation. Coal mill supplier in USA, India.

Every coal pulverizer is designed with a particular fuel grinding capacity or throughput at a certain Hardgrove grindability index (HGI), based on a defined raw coal ...

Williams pulverizers (roller mills) are perfect for pulverizing coal, minerals, limestone, phosphate, clay and more. Learn more about our coal grinder system.

GE Steam Power offers a range of technology for power mills, ... combustion was adapted for power generation—GE has been a leader in coal mill technology for the ...

This type of mill consists of a ... Raw coal enters the top of the pulverizer through the raw coal ... Coal pulverizer downtime can be a major factor ...

Coal Pulverizer, Coal Pulverizer Mill, Coal Mill Pulverizers. Machinery is a manufacturer of coal pulverizing equipment. The four most common types of coal ...

Coal Pulverizers. RPM Associates manufactures and rebuilds coal pulverizer parts for Combustion Engineering, Foster Wheeler, Babcock Wilcox, and Alstom bowl mills.

Manufacturer, exporter of pulverizers, Mica Pulverizer, RHA Pulverizer, Hard Coal Tar Pitch Pulverizer, Pulvigator, Pulverizing mill, roller crusher, ribbon blender ...

Optimum Operation and Maintenance of EL Pulverizers ... • Size of pulverizer coal particles leaving the ... During a mill fire, pulverizer air flow should not be

WhatsApp)

WhatsApp)